Our Testing Method

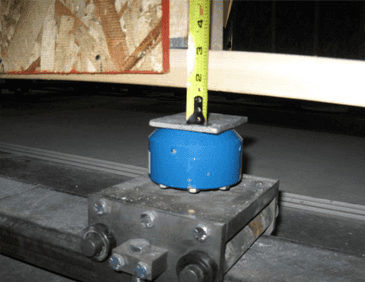

CBI’s testing quality control process revolves around accurate measuring. We measure:

- Applied loads placed on any component or structure.

- Loads as they pass though the element or assembly.

- All the reaction loads at each of the supports.

Measuring both load-in and load-out ensures we accurately account for all the forces exerted on and moving through the tested assembly.

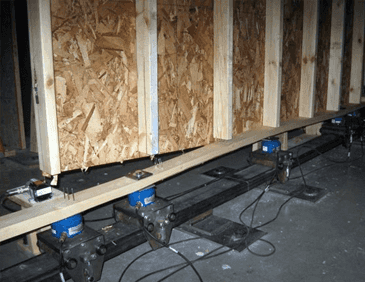

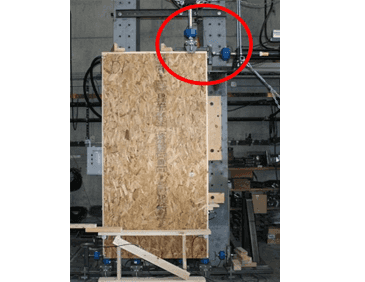

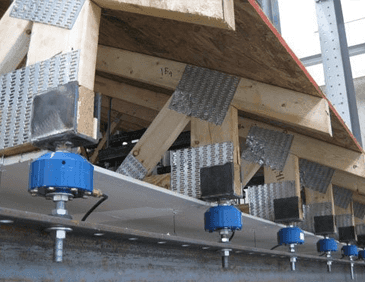

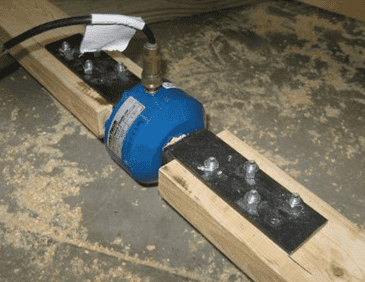

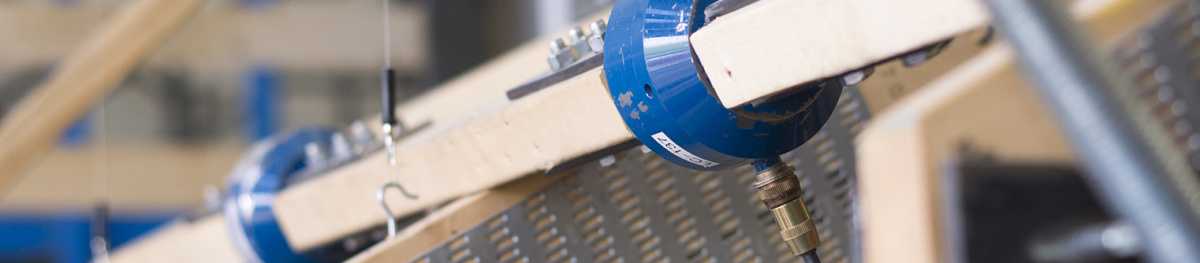

Our modular testing bay approach is at the heart of CBI’s innovative testing environment, making us truly unique in the marketplace. We like to think of it as the world’s biggest erector set – we modify our lab to meet the needs of your test instead of you tailoring your test to our lab. Inside this highly versatile space, we can test anything from single elements (like an individual nail or fastener) to fully-assembled structures constructed with those elements to gain a complete understanding of the actual performance of each element as it resists the fully-assembled structural system loads.

To collect performance data and perform product load path resistance evaluations, we have constructed multi-story roof and floor systems, with and without the building envelope sheathing/windows.

New product creation, interative R&D and forensic investigation testing have taken place at CBI, where the structural behavior (i.e., load-deformation, deflection, design strength, and ultimate strength evaluation) is monitored with great accuracy.

Contact us for a free needs analysis to get started.